Trusted Services

24/7 Support

Well Experienced

ABOUT SANGAM FORGING LTD RAIGARH

With a commitment to excellence, we provide precision-engineered components and equipment, ensuring durability and reliability for our clients. Our advanced manufacturing capabilities and stringent quality control processes enable us to deliver superior products that meet industry standards.

INDUSTRIES WE SERVE

Mill Stand, Choke, Rail, Hot Coiler Drum, Coupling, Pallet Car, Deflector, Adaptor, Sleeves, Garret Coiler Drum, Gear, Sprocket, Slag Pot, Grate Bar, Ingot Mould, Mould Basin, etc.

Spindle, Adapter & Tooth Point, Tooth Point, Front Axde, Axle Housings, Components Backhoe Loader, Track shoes, Tilt Lever, Cross Member, Flange, HUB Casting, Steering Case, Lift Arm, Supports, Hitch Sprocket, Swing jaw, Stationery Jaw Toggle, Pitman, Jaw plate, Side plate, etc..

Grinding Roller, Guide Vane, Turbine Casting, Turbine Body Casing, Plain & Toothed Ring hammer, Crushing Ring, Gears, Guide Roller, Trunion Hub, Trunion Packet, Trunion Pin, Rope Drum, Rope Pulley, Eye-Bolt, Gate Beam, etc

Comer Castings, Mold Plates, Impeller, Deflector, Heavy Pump Casing, Hydraulic Cylinder, Heavy Casting for Dairy And Food Processing Industries, Tooling (Die & Punch) for Bud Welded Pipe etc..

Stain Steel and Cast Iron Vessel, Cast Iron Ring Tower for Soda Ash & Fertilizer Plant, etc.

Cutting Edge, Apron Pan Assembly, Idler, Fork Type Comer Tools, Box Type Tooth Points, Jaw Plates, Deck Panel Continuous Drag Track Shoes, Track Shoes Assembly, Ring Hammer, Hammer, Linkage, Tri Power HUB, Track Link, Bearing Supports, Heavy Drive Sprocket and Idler Rollers for power shovel, etc..

Impeller, Diffuser, Valve Body, Wedge, Yoke, Bonnel, Pumps, etc..

Anchor& Shank Assembly, Segment Feeder, Container Comer, Bollard, Pivot, etc…

Linear, Drag Chain Links, Hammers, Cooler Grate Plates, Blow Bar, Jet Ring, Grinding Segment, Grinding Roller, Grinding Tire, Grinding Table Segment, Diaphragm Plate Cooler Plate & Segment Tips, Killen Tyre, Girth Gear, Supporting Rollers, End Header, Waler Cooled Bearing Housing, Yoke elc

Head Stock, Crown Pinion, Scraper plate, Trash plate, Knite, Sugar Cane Juice Roll/Roll Sleeve, etc.

Sangam Forging Ltd Raigarh

SERVICES PROVIDED BY US

Pouring Process

Fettling Process

Heat-Treatment Process

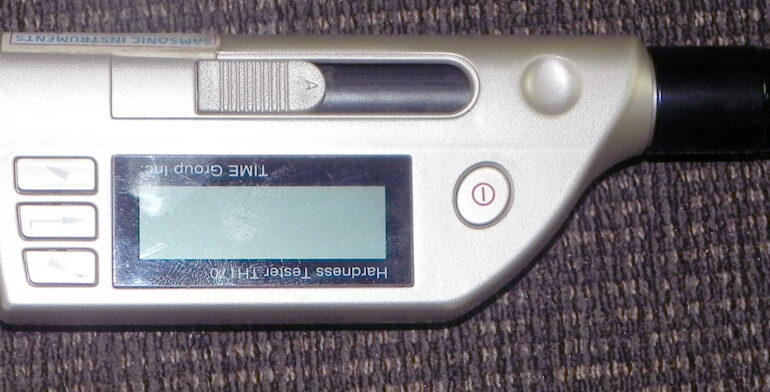

Quality Testing & Inspection

✅ Ultrasonic Testing (UT)

✅ Radiography Testing (RT)

✅ Magnetic Particle Inspection (MPI)

✅ Dye Penetrant Testing (DP)

Our Industrial Products